Hiring a Walkway for the Fascia & Guttering

With our ceiling being 3.6m above the floor, it means that fitting the fascia board and the guttering is nigh-on impossible on a ladder. Even with two people. In addition, it would be an un-safe work practice!

I made enquiries about hiring a suspended walkway that attaches to the wall frame. At first most companies wanted to fit the entire house with a continuous walkway, leave it in place for 10 days, and the taking it away. As you can imaging, this was expensive.

Finally, for about a quarter of the price, I hired (for two weeks) enough gear to do one 25m run of the house (the entire perimeter is 86m), and I installed and moved it myself. (I also transported it in my trailer). So, in about 4-moves, I was able to fit the fascia and the guttering around the house. Of course it took longer than I expected, and it also rained a lot. But in the end, I have made it, and saved money on the guttering and fascia installation.

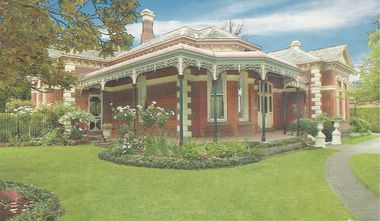

One technical note on fascia. We have chosen a timber fascia, even though colorbond steel is very popular now. Again, we wanted the traditional appearance. Fascia used to be made from Canadian oregan (spelling?). But hese days a better product is "finger jointed" LSOP pine. It is treated to prevent rot, and it is so, oh so, straight compared to oregan of recent times (sorry Canada!). The fascia is fitted so its top surface is 35mm above the top-chord of the trusses (our battens are 35mm).

Also, when ordering roof trusses, they have to leave about 50mm of top-chord protruding past the point where the fascia will be installed (this is so you can run a string line, and cut the top-chords off, giving a straight line for the facia). For metal fascia, they don't bother with this, as it has adjustable brackets to get it straight.

With the fascia and guttering now complete, the roof is ready to fit.

I made enquiries about hiring a suspended walkway that attaches to the wall frame. At first most companies wanted to fit the entire house with a continuous walkway, leave it in place for 10 days, and the taking it away. As you can imaging, this was expensive.

Finally, for about a quarter of the price, I hired (for two weeks) enough gear to do one 25m run of the house (the entire perimeter is 86m), and I installed and moved it myself. (I also transported it in my trailer). So, in about 4-moves, I was able to fit the fascia and the guttering around the house. Of course it took longer than I expected, and it also rained a lot. But in the end, I have made it, and saved money on the guttering and fascia installation.

One technical note on fascia. We have chosen a timber fascia, even though colorbond steel is very popular now. Again, we wanted the traditional appearance. Fascia used to be made from Canadian oregan (spelling?). But hese days a better product is "finger jointed" LSOP pine. It is treated to prevent rot, and it is so, oh so, straight compared to oregan of recent times (sorry Canada!). The fascia is fitted so its top surface is 35mm above the top-chord of the trusses (our battens are 35mm).

Also, when ordering roof trusses, they have to leave about 50mm of top-chord protruding past the point where the fascia will be installed (this is so you can run a string line, and cut the top-chords off, giving a straight line for the facia). For metal fascia, they don't bother with this, as it has adjustable brackets to get it straight.

With the fascia and guttering now complete, the roof is ready to fit.

0 Comments:

Post a Comment

<< Home