Downpipes

Of course the new rain-water collection pump has put the pressure on me to get all the downpipes finished. Most of them are done, but I had left the more difficult ones until last. Above is a photo of the downpipe that collects water from a gutter, and also from a sump located at the end of a "box gutter" in the roof (hence I have two pipes joining together). If the sump blocks-up, the over-flow water will run into the "rain head" shown in the photo too.

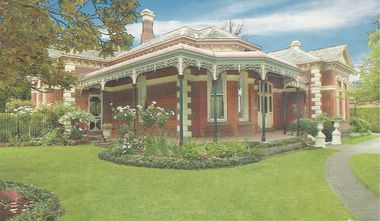

On the verandahs, we had to partially rebate each down-pipe into the "stringer-molds" that decorate this section of the house. It was a bit stressful, but it has turned out well. The verandah is yet to have the cast-aluminium lace-work fitted (another consideration in figuring how the downpipe should be fitted). The down-pipes are also "offset" from the brickwork by about 40mm, as the sandstone quoins protrude from the brickwork by about 25mm, and the down-pipe has to clear this at the top and bottom.